In today's healthcare environment, the importance of selecting the right Central Suction Machine cannot be overstated. According to a recent market analysis by Grand View Research, the global suction equipment market is expected to reach $1.12 billion by 2027, driven by advancements in technology and an increasing demand for efficient medical suction systems. However, navigating the myriad of production standards can be daunting for healthcare providers. The nuances in regulations, along with the need for compliance with stringent safety and performance criteria, require a well-informed approach to procurement. By understanding the key industry standards and leveraging essential tips for selection, healthcare facilities can ensure they choose a Central Suction Machine that not only meets their operational needs but also enhances patient care and safety.

When selecting a central suction machine, understanding the advantages of after-sales service is crucial. According to a report by the Association of Medical Device Manufacturers (AMDM), over 70% of buyers consider after-sales support as a deciding factor in their purchasing process. An efficient after-sales service can significantly extend the lifespan of these machines and reduce downtime, which is vital in fast-paced industrial environments.

Maintenance support, including timely repairs and access to spare parts, can enhance operational efficiency and overall productivity.

Moreover, the market data indicates that facilities with robust after-sales support report a 25% increase in operational efficiency compared to those without, as highlighted in the Industrial Vacuum Systems Report 2022. This improvement is largely attributed to the reduced need for emergency repairs and the enhanced ability to predict maintenance needs.

Therefore, investing in a central suction machine that comes with comprehensive after-sales services not only optimizes functionality but also ensures that businesses can adapt quickly to evolving production standards without sacrificing performance.

When selecting a central suction machine, understanding the repair costs associated with your choice can significantly impact your long-term savings. Initial purchase price is just the tip of the iceberg; maintenance, warranty, and potential repairs should all factor into your decision-making process. A machine with a low upfront cost may lead to higher long-term expenses if it requires frequent repairs or lacks adequate support. Evaluating the manufacturer's reputation for reliability and the availability of replacement parts can be key in determining how much you may invest down the line.

Additionally, consider the frequency and types of repairs that may arise. Machines with complicated mechanics or those that require specialized service can quickly become costly burdens. Conducting research on common issues reported by current users can provide valuable insights. Investing in a model designed for durability and ease of maintenance not only reduces downtime but also extends the lifespan of the equipment. Ultimately, taking a holistic view of repair costs and durability will help ensure that your central suction machine remains an asset rather than a liability.

This chart illustrates the estimated annual repair costs associated with different central suction machines. When selecting a machine, evaluating these costs can help ensure long-term savings and efficiency in operations.

When selecting a central suction machine, the significance of quality service cannot be overstated. The performance of these machines is directly influenced by the quality of the service provided throughout their lifecycle, from installation to ongoing maintenance. A recent systematic review highlighted that collaboration between healthcare organizations and service providers can lead to improved health outcomes and enhanced performance of medical equipment. Ensuring that your central suction system is supported by a proficient service team can prevent downtime and ensure optimal functionality, ultimately improving patient care.

**Tips:** It's essential to choose a provider that offers regular maintenance schedules and quick response times for repairs. Investigate service-level agreements (SLAs) that guarantee uptime and support. Additionally, training for your staff on best practices for using the central suction machine can help in maximizing its performance and longevity.

Furthermore, data from industry reports indicate that facilities that invest in quality service for their suction systems report a 20% increase in operational efficiency. This statistic underscores the critical role that consistent and professional maintenance plays in fostering effective healthcare delivery. As healthcare facilities strive to enhance their service quality, integrating a solid service framework for central suction machines is essential to meet both industry standards and patient expectations.

**Tips:** Assess your service provider's track record with similar equipment and ensure they have qualified technicians. Regular feedback from end-users can help identify areas for improvement and facilitate better collaboration.

| Feature | Description | Performance Metric | Standard Compliance |

|---|---|---|---|

| Suction Power | The strength of vacuum created | 500-800 mmHg | ISO 7396-1 |

| Noise Level | Noise generated during operation | < 65 dB | ISO 11364 |

| Energy Efficiency | Energy consumed during operation | 60-120 W | Energy Star Rated |

| Maintenance Requirement | Frequency of required maintenance | Every 6 months | N/A |

| Warranty Period | Manufacturer warranty duration | 2 years | N/A |

When considering the best central suction machine for your needs, it's essential to navigate the different production standards and warranty options available. Warranty coverage can significantly impact your long-term satisfaction and cost-efficiency. Most home warranty providers now offer straightforward protection plans with simple fees, ensuring homeowners can easily understand what is covered. Coverage often includes essential systems and appliances, which can shield you from unexpected repair costs.

Tips for selecting the right warranty include reviewing the specifics of what each plan covers. Look for policies that cover both parts and labor for major systems, such as HVAC and plumbing. Additionally, consider the service fee associated with each claim; lower fees can save you money in the long run.

Furthermore, it's beneficial to compare customer reviews and ratings of warranty companies to gauge overall satisfaction and value offered. This approach can lead to more informed decisions, ensuring you select a warranty that fits your needs while providing reliable protection for your home systems and appliances.

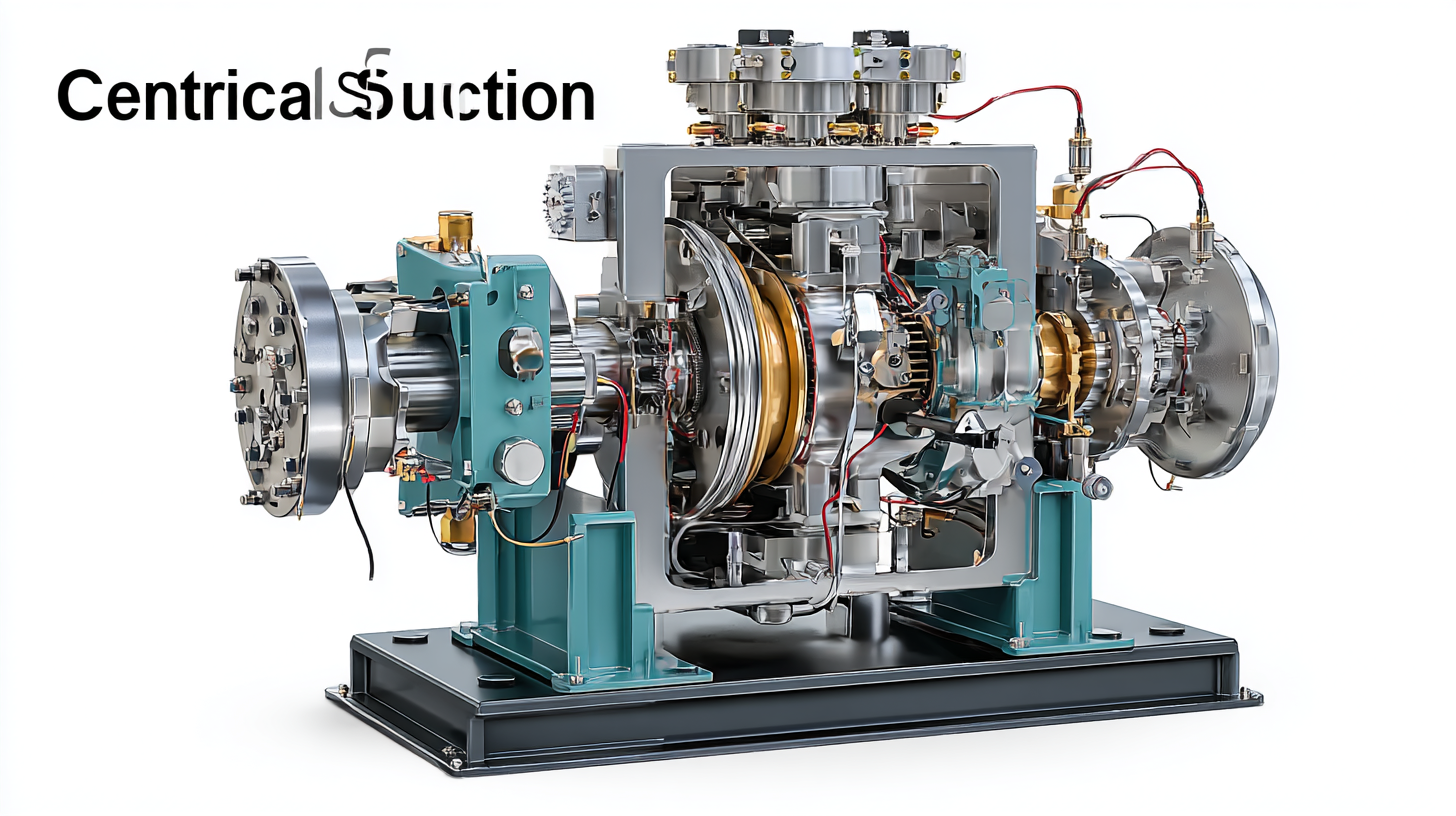

Maintaining a central suction machine is crucial for maximizing its lifespan and ensuring optimal performance. According to a report by the American Society of Mechanical Engineers, regular maintenance can reduce repair frequency by as much as 30%. Essential practices include routine inspections of your machine's filters, vacuum pumps, and hoses. Ensuring that these components are clean and free from blockages not only improves the efficiency of your suction system but also helps avoid unexpected breakdowns, which can be costly both in terms of repair bills and operational downtime.

Additionally, staying updated with the manufacturer's maintenance guidelines can provide vital insights into specific needs for your model. A study by the National Vacuum Equipment Association found that proactive maintenance, such as lubricating moving parts and replacing worn components, can lead to a 25% reduction in total operating costs over the equipment’s lifespan. By adopting these common maintenance practices, businesses can navigate production standards more effectively while ensuring their central suction machines operate at peak performance.